About Us

The Most Advanced Patented HVAC Thermal Transfer Technologies for Restoring Lost Capacity and Improving System Efficiency While Extending Equipment Life

Additional Information

In today’s highly competitive business environment, reducing fixed operating expenses is no longer an option if your company wants to remain a viable entity. Tri-S Corporation Premier HVAC performance solutions offers the most advanced and comprehensive turn-key program to significantly reduce your HVAC-R operating costs.

Over 25-years ago, Tri-S Corporation founder Tony Sgarbi developed the first ever successful technologies in the thermal transfer restoration market and has remained the unquestioned leader to this day. In 2015, Mr. Sgarbi developed his fourth-generation family of technologies under the brand name CryogenX4, specifically CryogenX4-TTT and CryogenX4-ACT. Following two years of thorough laboratory and field testing, these revolutionary new technologies were made available for installation in late 2017. The CryogenX4 family of technologies combine the best aspects of the Tri-S Corporation’s four previously patented technologies (Permafrost was the 3rd generation technology) with the very latest in chemical engineering breakthroughs to create the most effective HVAC system thermal transfer restoration technologies ever produced. Used in tandem, these technologies create a fully optimized “push-pull” heat transfer flow that restores lost cooling capacity while improving system efficiency and extending equipment life.

Facts about HVAC SYSTEMs

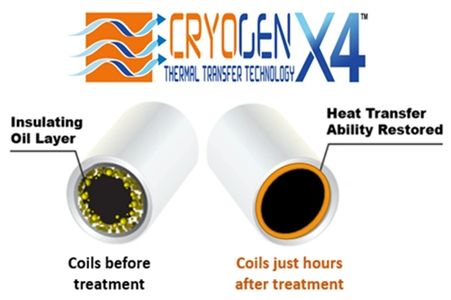

Even with the best preventative maintenance schedules to keep your HVAC systems in good external operating condition, every HVAC system still begins losing vital cooling capacity from day one. This is mainly due to constant oil migrating from the compressor(s) into the heat transfer coils on both the evaporator and condenser sides of the system (fig.1). In just a few short years this migrating oil leads to a loss of up to 20% or more in cooling capacity (tonnage) and efficiency (kW/ton rating) from original design.

This inherent performance degradation also leads to:

- Increased energy consumption. This translates into pure wasted energy and leads to increased greenhouse gas emissions. You pay more and cool less!!!

- Increased wear and tear on the HVAC equipment. This usually means additional emergency maintenance due to excessive heat buildup, failures of compressors, increased friction, issues with expansion valves, drier filters and other related issues.

- Shorter HVAC equipment life. This means higher Capital and Operational expenses being incurred by the company over time.

Two Options for Restoring HVAC Capacity

First, you can spend thousands of dollars to replace your existing commercial HVAC systems with new, higher efficiency units, which is what the HVAC equipment manufacturers count on you to do over and over again. The other option is to only spend a fraction of the unit-replacement costs on the best proven efficiency restoration solutions — CryogenX4-TTT and CryogenX4-ACT. Both products are specifically designed to enhance the overall performance of any HVAC equipment without modification or alteration. In addition to restoring cooling capacity by removing the majority of oil fouling (fig.2), these fourth-generation nanotechnologies help reduce HVAC run-time by removing humidity faster and cooling the air quicker. Best of all, any HVAC equipment treated with the CryogenX4 products are covered by Tri-S Corporation’s million-dollar lifetime warranty.

CRYOGENX4-TTT (Thermal Transfer Technology)

The internal parts of an HVAC unit, specifically the condenser and evaporator exchangers, are designed to transfer heat. Oil migration and other chemicals continually infiltrate these systems and form an insulating layer that hinders the heat transfer capabilities of the evaporator and condenser heat exchangers. When CryogenX4-TTT is introduced into a system, its highly conductive, electromagnetic and polarized molecules forever displace the insulating layer of non-conductive material. These polarized molecules prevent refrigerant oil buildup from ever reoccurring. The result is a metal surface free of efficiency-robbing, stagnant oil with enhanced heat transfer properties. In addition, CryogenX4-TTT delivers enhanced lubricity, allowing compressors to run at cooler temperatures by re-circulating refrigerant at a colder rate. By reducing the negative effects of extreme heat, the HVAC system life is also extended.

The enhancements of CryogenX4-TTT over its previous technologies include the following:

- Improved compatibility with all prevalent industry refrigerants

- Improved thermal transfer through better molecular structure adhesion

- Improved lubricity (>500%) and protection on all types of internal metal surfaces

- Superior new chemical stabilizers & deactivators to protect internal seals

- Elimination of adverse effects due to unintentional cross-contamination

- Enhanced acid neutralizing chemical compositions in case of system moisture

Simple Installation Delivers Powerful Results

CryogenX4-TTT is a one-time application that is installed while the HVAC systems are running. There is absolutely no downtime or interruption to business operations during installation. Once it is allowed to properly absorb into the metal surfaces of the equipment, CryogenX4-TTT lasts for the life of the unit. Changing refrigerants or the oil reservoir in a system at this point will not affect the technology as it has now become an integral part of the system.

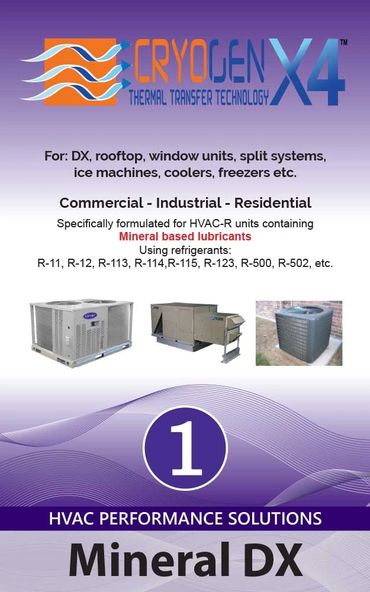

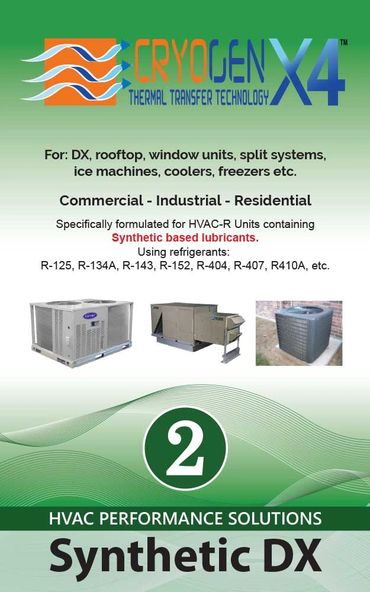

As illustrated on the labels shown below, there is a CryogenX4-TTT product for any HVAC scenario. Not shown are Tri-S Corporation’s mineral and synthetic-based chiller products as well as their specialized product for Ammonia systems.

All of the CryogenX4-TTT products will yield energy reductions at-the-unit of between 10% to 30%, depending on the age and runtime of the equipment. The savings will be even greater when used in conjunction with annual CryogenX4-ACT treatments. These direct HVAC unit savings usually result in overall average savings of 8-15% off the total utility bill.

CRYOGENX4-ACT (Active Coil Technology)

CryogenX4-TTT focuses on the interior surfaces of HVAC systems while its complementary technology, CryogenX4-ACT focuses on the coils exterior. Evaporator coils on an HVAC system inside of a building capture heat from the air inside the building while condenser coils on a unit outside the building release that captured heat into the atmosphere (fig.1). These coils are usually made of copper and are surrounded by a series of aluminum fins that facilitate heat transfer.

Evaporator coils are vitally important to the cooling performance of your air conditioning system and in the dehumidification your air conditioner provides, especially when temperatures are at their hottest and most humid. As these coils become cooler, water condenses on them and is removed from the air. Air blowing across coils can contain dust, pollen and other particulates. Since coils are usually damp from the dehumidification process, it’s very easy for contaminants to stick to them. Dirty air filters in the system (or the lack of filters entirely) can also increase the amount of material that makes contact with the coil. When evaporator coils get dirty, their cooling and dehumidification performance is significantly reduced. Problems include:

- Significantly reduced heat transfer

- Decreased cooling capacity

- Increased energy consumption

- Increased operating temperatures & pressures

- Build-up of ice on the coils

- Reduced life expectancy & component damage

CryogenX4-ACT is the most advanced technology designed to clean and activate the coils on the outside of any HVACR system. The ‘activator’ improves the coils heat transfer rate through a ‘coating’ of highly-conductive molecular compositions. Simple and safe, it is a bio-degradable spray-on solution applied at regular maintenance intervals on the outside metal surfaces.

Disclaimer

The Tri-S family of products have been proven safe and effective in reducing HVAC-related energy cost over 20+ years in service, 150,000+ installations, and by multiple national laboratories when implemented according to the company's instructions. Tri-S Technologies is not responsible for resulting actions when deviating from the aforementioned instructions.

Copyright 2020 by TRI-S Technologies, LLC. All rights reserved.

TRI-S TECHNOLOGIES 2020