ELECTROGENX4-PCU (POWER CORRECTION UNIT)

INTRODUCTION: ~ INTERNAL POWER CHALLENGES AND COST

Commercial power customers are today faced with the challenges of electrical power and consumption delivered through inefficient processes and methods. Equipment used is typically neither of poor design nor in most cases used incorrectly. Companies that are truly concerned about power inefficiencies and subsequent cost look to the source of their problems to address them with the most cost- effective solutions available. This translates to higher efficient lighting, management systems that actually control equipment usage, more efficient motors when applicable, less costly cooling and importantly, custom designed energy reduction applications that addresses their entire facilities.

To understand the efficiency opportunities to be gained, knowledge of one’s operating environment and its effects on power quality at the load must be known. Power quality mandates a set of boundaries to permit electrical systems to function in their intended manner without significant loss of performance or operating life.

Power entering a building is subject to all interferences inside that facility. The distribution system inside your building must be able to handle the deviations of delivered power quality and the way power behaves when it reacts to different types of equipment in the circuitry. Typical symptoms causing behavioral inefficiencies, losses and disruptions are sags and swells and surges and resonance, harmonics, reactive power and phase unbalance. All exist naturally in most electrical networks due to modern equipment and machinery usage. The end result is that power utilities typically provide more power to end-users to produce the same amount of work.

POWER PROVIDED VS POWER REQUIRED

When power provided exceeds power required one unnecessarily pays for more energy. The power required calculation to operate your building or facility to produce the necessary work is inevitably significantly lower than the utility company’s provision i.e. power provided. This usually occurs by not taking into account the facility’s power interferences and built-in inefficiencies. The objective is to get power provided close to power required calculated to save unnecessarily wasted money. Typical commercial clients’ actions to compensate for poor electric power quality inside their facilities are:

- Traditionally … do nothing

- Purchase more efficient lighting, motors, variable frequency drives (VFD), and heating, ventilation, air conditioning and refrigeration (HVACR) systems, usually post equipment failure

- Install capacitor banks to improve power factor correction (PFC) at the utility’s service entrance to eliminate any utility power factor penalties

- Install harmonic filtering to treat specific frequencies present in circuits. However, this expensive treatment only addresses one issue, which is common with actions taken by our clients

ELECTROGENX4-PCU (POWER CORRECTION UNIT)

ELECTROGENX4-PCU handles power quality inside your facility by treating each and every significant load’s behavior of power interference and/or poor power quality that causes needless consumption and wasted money. By separate treatments, it prevents the poor power quality from reaching the load, filters the power and keeps the load interferences from leaving to cause poor power quality elsewhere. By treating the power quality throughout the entire facility, ELECTROGENX4-PCU reduces the utility power amount provided and thus lowers the power paid for amount

ElectrogenX4-PCU is a least-cost improvement approach, which:

- Reduce the load power usage

- reduces the load startup demand for power

- reduces the load noise total harmonic distortion

- Improves the load phase power factor

- Reduce the load transient anomalies

- Provide a more constant alternating current (AC) wave form

ELECTROGENX4-PCU electro-technology is used in conjunction with a wide variety of equipment. Paying close attention to the small details, it consistently improves client's electricity usage.

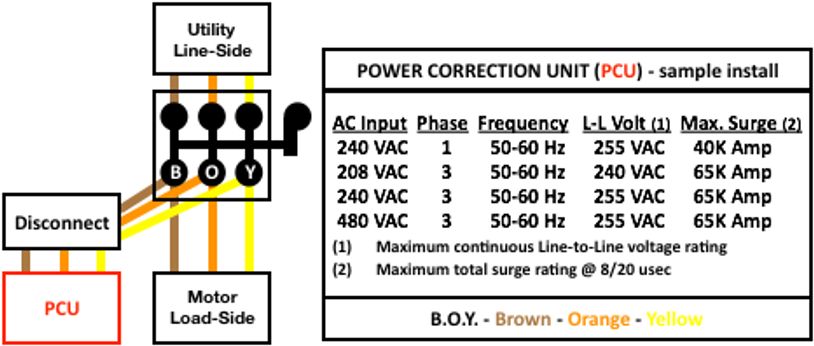

ELECTROGENX4-PCU is placed in parallel in facility power distribution AC system sub-panels and is also designed to be installed on individual equipment types such as large induction motors for HVACR.

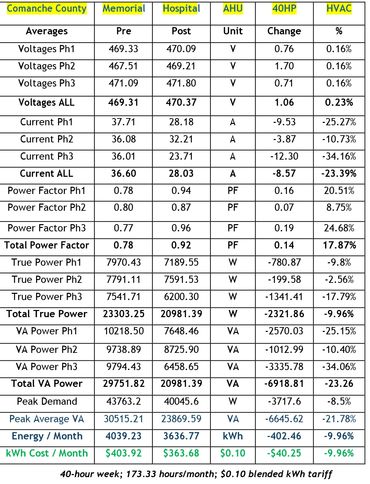

ELECTROGENX4-PCU effects KVA reduction, kWh consumption and load demand in addition to TVSS (transient voltage surge suppression). It typically yields post installation real kilowatt 8% - 15% savings in equipment such as the Air Handler Unit (AHU) above.

ELECTROGENX4-PCU provides surge and spike suppression, noise reduction, line filtering and power factor correction for 120VAC single phase to 600VAC 3-phase commercial applications. AC filtering aids in the electrical performance of various loads because the capacitive reactance of the filter offsets the inductive load reactance to balance the phase variation caused by the inductive load.

Surge and spike protection is achieved through two (2) metal plates surrounded by ceramic material acting as a short circuit to channels additional current and stop voltage increases at a low enough level to prevent damage to equipment. The protection provided response is as little as ten (10) nanoseconds (ten millionths of a second).

ELECTROGENX4-PCU provides complete clamping voltage for total surge rating to occur within 8-20 µsec from 40-100K amps. The Power Factor is improved as well as the voltage-current relationship.

Technical

ELECTROGENX4-PCU relates generally to the field of alternating current (AC) line filters and surge suppression circuitry, and more particularly to the application of line filtering based upon a pre- determined sensed inductive current at the load. The AC line filter preferable capacitance range is 5-285 µF (microfarads). The basic alternating current (AC) line inductive-capacitive (LC) filter circuit inserted in the power supply filters out unwanted high-frequency interferences present in the input line supply. Line filters also aid in the reduction of voltage spikes or "surges", as well as aid in the elimination of radio frequency (RF) interference by the power supply.

Line filters are typically placed before the transformer of a power supply to prevent these unwanted signals and spikes from reaching the load. The difficulties encountered when AC voltage surges occur in power supplies are well known. Sudden spikes or dips in the input voltage are particularly problematic to sensitive circuitry such as digital integrated circuits, but are also problematic to larger scale circuitry. A change in the power supply output voltage, particularly sudden increases in output voltage, may damage or destroy circuit components. Power supply regulation prevents and/or minimizes the effect of power surges to maintain a constant output voltage regardless of load.

Transient voltage surge suppression (TVSS) technology is used for surge protection, very useful on a continuous basis for equipment connected to a power line.

Additional AC filtering is achieved by including capacitive filtering in the line. Capacitive filters further aid in the electrical performance of various inductive loads such as pumps, fans, air conditioning units, refrigeration units, etc. as the capacitive reactance of the filter offsets the inductive load reactance to balance the phase variation caused by the inductive load.

Problems of varying load-operating parameters have also been addressed with motor control circuitry. Examples include variable frequency drives (VFDs), and “soft-starts” which do not allow full transfer of power upon start-up, but instead slowly ramp up power to the load. Although such control circuitry may provide significant energy savings, it often requires changing the frequency of and/or the voltage supply to the load and does not address the need for control of the line filtering application

Conclusion

ELECTROGENX4-PCU combines the above technology with additional proprietary methods and circuitry to achieve equipment benefits such as a reduction of power usage by the load, a reduction of load start-up demand for power, an improvement of the load phase power factor, a reduction of line transient anomalies and the provision of a more constant AC waveform and a reduction of noise and total harmonic distortion (THD) at the load. Filtering reduces the operating temperature which is known to extend the useful life of the load. The flexibility allows for use in conjunction with a wide variety of inductive load equipment. The payback is typically 12 – 18 months.

Disclaimer

The Tri-S family of products have been proven safe and effective in reducing HVAC-related energy cost over 20+ years in service, 150,000+ installations, and by multiple national laboratories when implemented according to the company's instructions. Tri-S Technologies is not responsible for resulting actions when deviating from the aforementioned instructions.

Copyright 2020 by TRI-S Technologies, LLC. All rights reserved.

TRI-S TECHNOLOGIES 2020